Industrial Manipulators for Safe and Ergonomic Handling of Pallets

Dalmec industrial manipulators are used worldwide to lift, orient, stack, and position wooden, plastic, and metal pallets—including Euro, half-pallets, skids, collars, and dunnage—across building-materials plants and high-throughput packaging lines. With application-specific gripping devices, operators can pick, rotate, tilt, and precisely place loads from 5 kg up to 900 kg, streamlining tasks such as depalletising, pallet feed to wrappers and palletisers, changeovers, line clearance, and repair while reducing strain and improving safety.

At Dalmec, safety and customization are at the core of every solution. All manipulators are manufactured in conformity with UNI EN standards, EC ATEX directives, and international safety guidelines. From functional analysis and technical design through simulations, prototype creation, and final implementation, our engineers work in close partnership with clients—performing continuous checks and reviews throughout development—to deliver state-of-the-art handling systems tailored to specific production needs.

Dalmec Manipulators for Pallets in the Building Industry & Packaging

Dalmec manipulators for pallets provide safe, ergonomic, and efficient handling in brick and block plants, tile and stone lines, bagged cement and adhesives operations, and end-of-line packaging cells. Tooling options include fork-style tines for empty or loaded pallets, side-clamp grippers for secure carry and stacking, vacuum frames for interlayer sheets and slip-sheets, and tilting/rotating heads for precise placement in confined spaces or onto conveyors. Systems can be configured for low-headroom areas, dusty environments typical of building materials, wash-down or stainless-steel finishes for food/packaging zones, and ATEX-rated setups where required. Whether feeding automated palletisers, unstacking return pallets, positioning collars and interlayers, or supporting rework and maintenance areas, Dalmec solutions enable continuous, reliable operation and measurable gains in safety, quality, and productivity.

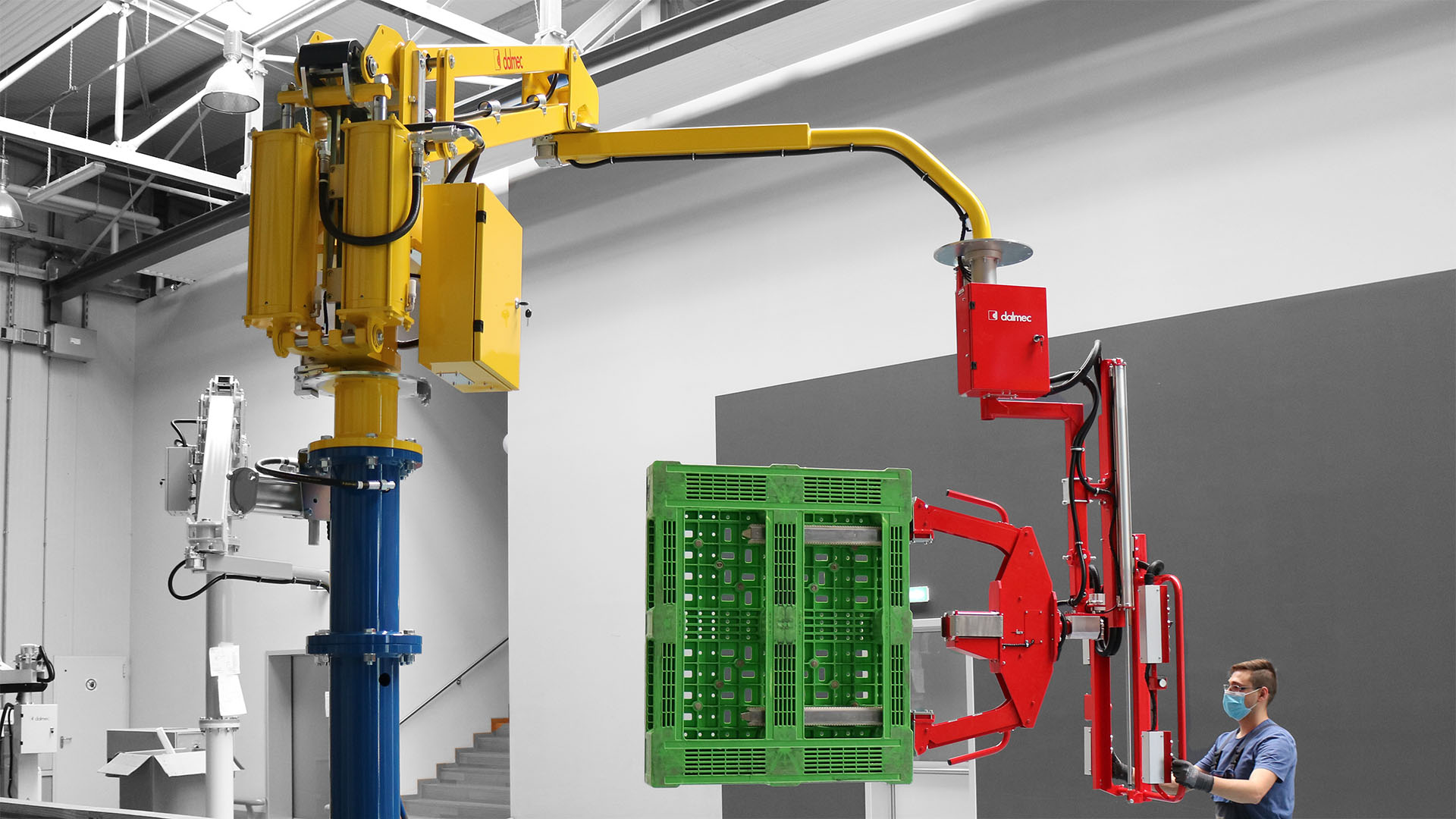

Handling Device for Pallets — Partner Manipulator (Packaging/Building)

A Dalmec Partner manipulator, typically column-mounted and fitted with adjustable fork tooling, enables ergonomic gripping, stacking and transfer of pallets with varying dimensions across packaging lines and building-materials plants, providing smooth weight-balanced control for fast, safe handling.

Pallets — Pneumatic Partner Manipulator with Adjustable Forks

This pallet handling solution uses a pneumatic Partner manipulator—floor-fixed in column execution with adjustable forks—to lift, position and re-stack different pallet types efficiently, supporting reliable end-of-line operations and warehouse workflows.