WELCOME TO DALMEC LIMITED

Industrial Manipulators for Weightless, Safe Material Handling

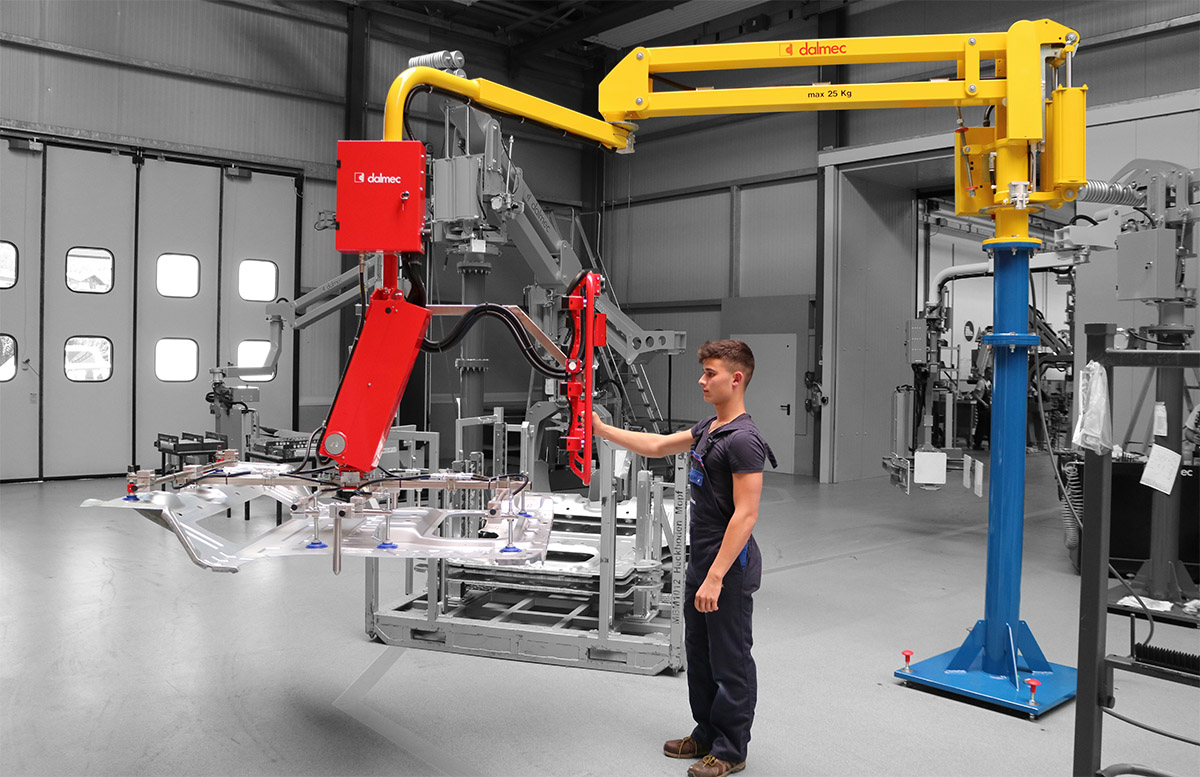

Dalmec is a world-leading designer and manufacturer of pneumatic industrial manipulators. We build bespoke lift-assist systems that let operators lift, rotate, tilt and position loads with precise, weight-balanced control—reducing manual handling risk while improving productivity and quality.

OUR RANGES

Dalmec Industrial Manipulators

Dalmec offers a complete range of industrial manipulators in the UK with rigid arms or cable, and each solution is custom-built with the design, dimensions and picking system adapted to your specific requirements and operating environment.

Manipulators with Rigid Arms

Rigid arm manipulators are designed for stable, controlled handling where precise positioning matters, particularly for heavier or off-centre loads and applications that benefit from controlled rotation and inclination.

-

Micropartner Manipulator (up to 125kg)

-

Partner PS Manipulator (up to 250kg)

-

Partner Equo Manipulator (up to 550kg)

-

Maxipartner Manipulator (up to 900kg)

-

Megapartner Manipulator (up to 1500kg)

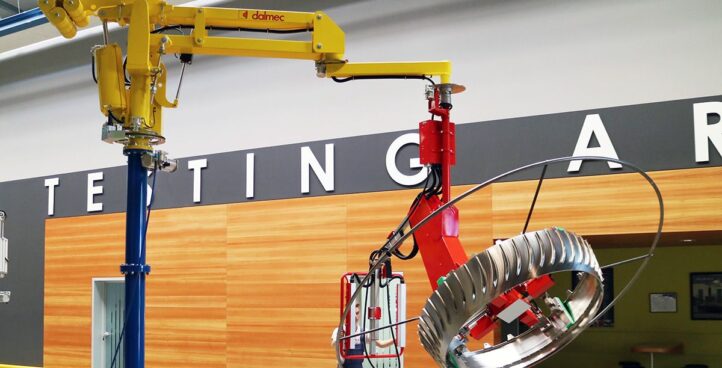

Manipulators with Cable

Cable manipulators are typically selected for fast, ergonomic handling across a wide working envelope, making them well suited to repetitive lifting and positioning tasks where ease of use is a priority.

-

Posifil Manipulator (up to 60kg, up to 140kg)

-

Posivel Manipulator (up to 60kg)

-

Posiplus Manipulator (up to 200kg)

-

Speedyfil Manipulator (up to 80kg)

-

Minipartner Manipulator (up to 80kg)

How to Choose the Right Industrial Manipulator

Choosing the right industrial manipulator is much easier when you break it into a few clear decisions, and we are here to help you through each step. It starts with the load: the true weight range, including the heaviest worst case, where the centre of gravity sits, and how the product should be held using vacuum, jaws, clamps or magnetic gripping. If the item is delicate, we will also factor in anti-marking contact and controlled clamping forces.

Next, it is about the movement. Tell us where you are picking from and placing to, such as pallet to machine, line feeding, staging or assembly, and whether you need rotation or tilt for orientation and alignment. We will then map the working envelope, including reach, lift height and any obstructions, and recommend the most suitable mounting option for your workspace, whether that is floor, overhead or trolley and rail.

Finally, we will consider the operating environment and duty cycle. If you have hazardous-area requirements, including ATEX where applicable, hygiene constraints such as stainless or washdown, or a high number of lifts per hour across multiple shifts, we will build that into the specification so the solution is safe, compliant and reliable long term.

COMMON APPLICATIONS

Dalmec Industrial Manipulators for Safe, Controlled Load Handling

Dalmec industrial manipulators are configured around the handling task, the load and the workstation layout, so operators can lift, orient and position with controlled, weight-balanced movement. From reels and drums to boxes, panels and components, we match the manipulator family and end-effector tooling to the application to support safer handling, repeatable placement and efficient workflows.

WHY CHOOSE US

A UK Partner for Reliable Material Handling Solutions

Weightless Handling

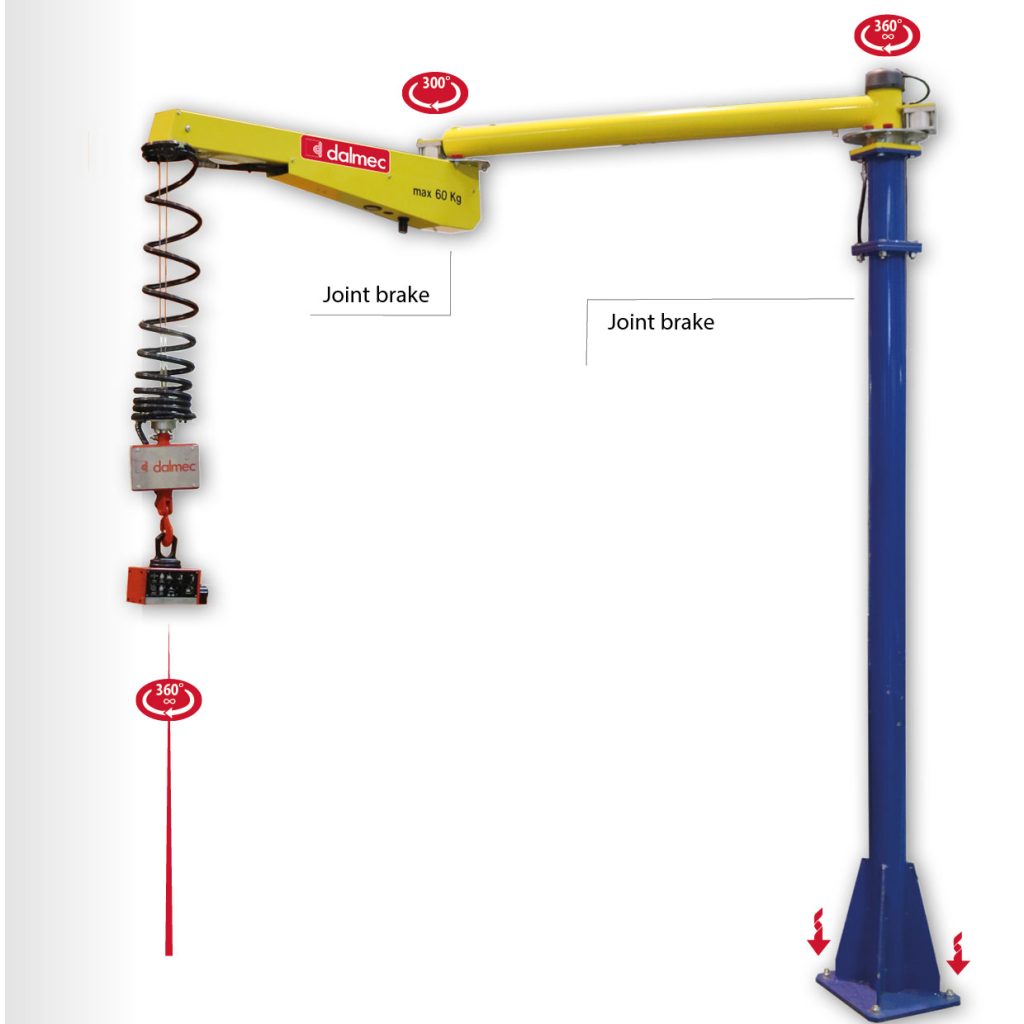

Dalmec Manipulators handle components “weightlessly” and can be fixed to the floor, overhead, or trolley-mounted on rails.

Full Range of Motion

Dalmec Manipulators are fully versatile offering 360° rotation of the main and intermediate axes, with a maximum radius of up to 5 metres.

Impressive Load Capacity

Dalmec Manipulators handle loads from 10 kg to 1500 kg, ideal for handling anything from small parts to heavy components safely and efficiently.

Custom Tooling & Precision Control

Dalmec customised tooling enables manual or pneumatic movement with up to 360° rotation and inclination of components, providing full orientation.

Certifications & Compliance

Dalmec manipulators comply with EC Machinery Directive 2006/42/CE, EN ISO 9001:2008, EN ISO 14001:2004, LOLER, PUWER, and hold CHAS and SafeContractor accreditations.

INDUSTRIES WE SERVE

Dalmec Industrial Manipulators for Every Industrial Environments

At Dalmec Limited in the UK, we specialise in supplying industrial manipulators and materials handling solutions tailored to the needs of a wide range of industries. Our bespoke systems, including lift assists and lifting equipment, are designed to improve efficiency, enhance operator safety and reduce the physical strain associated with manual handling tasks. Backed by decades of engineering expertise, we deliver durable, reliable solutions with UK-based support to keep operations running smoothly.

FREQUENTLY ASKED QUESTIONS

Answers to Common Industrial Manipulator Questions

What is an industrial manipulator?

An industrial manipulator is a sophisticated lift-assist device used to handle heavy, awkward, or offset loads that cannot be moved manually or with a standard hoist. Unlike a simple crane, a manipulator allows an operator to lift, rotate, tilt, and manoeuvre a component with precision, often providing a “weightless” feel. This is achieved through a rigid arm system that counteracts the weight of the load, making it an essential tool for high-cycle production lines and complex assembly tasks.

How does a pneumatic industrial manipulator work?

Pneumatic manipulators, like those designed by Dalmec, use compressed air to power the lifting and balancing mechanism. They operate on a “weightless” principle where the air pressure is adjusted to balance the specific weight of the load. This allows the operator to move the item by hand as if it weighed nothing. Because they are purely pneumatic, they are often preferred in ATEX-rated hazardous environments where electrical components could pose a risk.

What are the main benefits of using a lift assistor?

The primary benefit is the significant reduction in workplace injuries. By removing the physical strain of manual handling, industrial manipulators help prevent Musculoskeletal Disorders (MSDs) and Repetitive Strain Injuries (RSI). Beyond safety, they improve operational efficiency by allowing a single operator to handle loads that would otherwise require two people or a much slower overhead crane system.

Can industrial manipulators be customised for specific tasks?

Yes. Unlike standard lifting equipment, the most effective industrial manipulators are bespoke. At Dalmec, we design custom “end-effectors” (gripping tools) tailored to the specific geometry of the product—whether it’s a car engine, a roll of film, a heavy box, or a chemical drum. This ensures the load is held securely and can be manipulated into the exact orientation required for the next stage of production.

Do Dalmec manipulators comply with UK safety regulations?

Absolutely. All our installations in the UK are designed to meet and exceed strict safety standards, including the Manual Handling Operations Regulations, LOLER (Lifting Operations and Lifting Equipment Regulations), and PUWER (Provision and Use of Work Equipment Regulations). Our systems also carry the necessary CE/UKCA markings to ensure full compliance with the Machinery Directive.