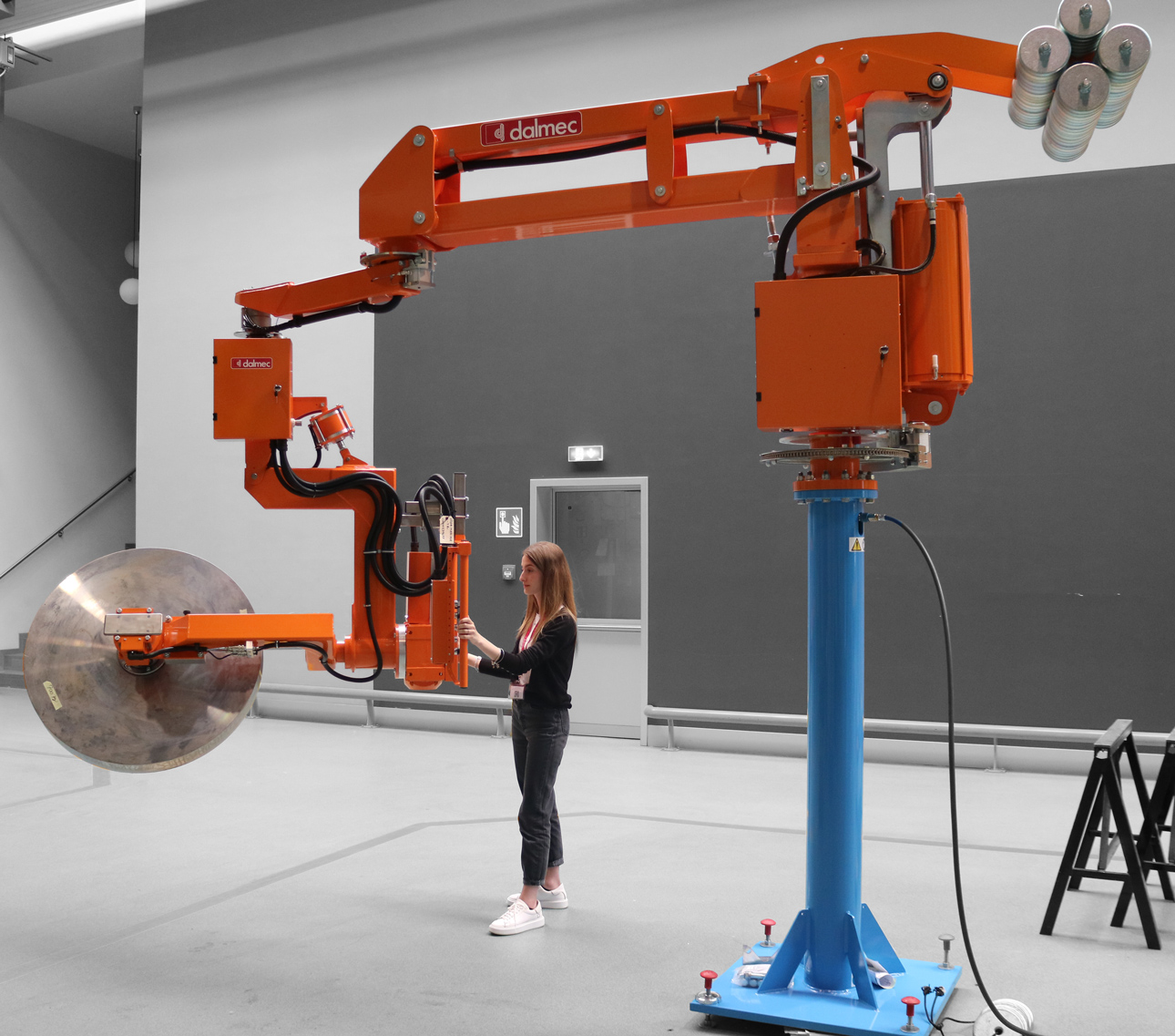

Industrial Manipulators for Safe and Ergonomic Handling of Mechanical Components

Dalmec industrial manipulators are used worldwide to lift, orient, and position mechanical parts of all shapes and sizes—castings, machined components, sheet-metal assemblies, gears, housings, shafts, engine blocks, and more. With application-specific gripping devices, operators can lift, rotate, tilt, and precisely place loads from 5 kg up to 900 kg with ease. Every system is engineered to increase throughput while providing ergonomic support and reducing operator strain.

At Dalmec, safety and customization are at the core of every solution. All manipulators are manufactured in conformity with UNI EN standards, EC ATEX directives, and international safety guidelines. From functional analysis and technical design through simulations, prototype creation, and final implementation, our engineers work in close partnership with clients—performing continuous checks and reviews throughout development—to deliver state-of-the-art handling systems tailored to specific production needs.

Dalmec Manipulators for Mechanical Parts

Dalmec manipulators for mechanical parts enable safe, ergonomic, and repeatable handling across machining cells, press shops, assembly lines, paint and coating areas, heat-treatment departments, warehouses, and logistics cells. With dedicated tooling—such as soft-jaw mechanical grippers for delicate machined faces, expanding mandrels for bores, magnetic or vacuum grippers for flat surfaces, adjustable clamps for irregular geometries, and tilting/rotating heads for precise orientation—operators can pick, index, and place components of varying sizes without damage or contamination.

Options include stainless-steel and food-grade finishes where required, ATEX-rated configurations for solvent or paint environments, ESD-conscious designs for sensitive assemblies, and low-headroom solutions for tight spaces. Whether loading/unloading CNCs, positioning parts in jigs and fixtures, feeding presses and robotic cells, or rotating components for inspection and assembly, Dalmec solutions enable continuous, reliable operation and measurable gains in safety, quality, and productivity.

Posivel Manipulator for Hydraulic Valves

A Posivel PVF fixed-overhead manipulator with a concentric jaw tool grips the valve on its inner diameter and lets operators balance, position and assemble hydraulic valve bodies up to about 60 kg quickly, safely and with minimal effort.

Lifting Device for Metal Rounds (Maxipartner MXC)

A Maxipartner MXC manipulator—engineered for heavy cylindrical stock—provides effortless, ergonomic lifting of metal rounds (up to ~700 kg, or ~900 kg with special tooling) to boost productivity and handling safety on the shop floor.

Handling of Valve Components (Partner, Column-Mounted)

A Partner manipulator in column-mounted execution uses interchangeable suction-cup heads to pick, orient and assemble large hydraulic-valve components with fast, accurate and safe motion across the working envelope.

Axles – Industrial Manipulators for Mechanical Parts

Custom-built Dalmec manipulators with tailored grippers and dimensions enable quick, precise and safe handling, rotation and transfer of axles and other mechanical parts across the full working area to match process and site conditions.

Bearings – Mechanical Components

Designed for weightless, ergonomic handling, Dalmec solutions for bearings pair application-specific gripping with smooth operator control to lift and position components efficiently while reducing strain and risk.

Lifting Device – Mechanical Parts

This pneumatic lifting device combines a custom gripper with precise balance control to pick, move and rotate mechanical parts quickly and safely, improving throughput in machining and assembly cells.

Round Workpieces – Manipulator for Mechanical Parts (Micropartner MIS)

An overhead-trolley Micropartner MIS with a pneumatic gripper enables effortless picking and transfer of round mechanical workpieces, providing accurate positioning without floor obstructions.

Manipulator for Gears (Machine-Tool Loading/Unloading)

Dalmec builds custom manipulators with grippers and stroke tailored to gear geometry and machine layout, allowing operators to load, flip and place gears reliably and ergonomically at the machine tool.