Ergonomic Lift Assists for Safe and Continuous Textile Production

The textile industry requires the handling of heavy and bulky loads such as fabric rolls, reels, and cloth materials that must be lifted, rotated, and positioned with precision. Manual handling of these products can slow production, cause damage to delicate textiles, and expose operators to repetitive strain or injury.

Dalmec industrial manipulators are engineered to meet these challenges, offering customised pneumatic systems designed around the specific movements of each client’s production process. By ensuring weight-balanced, ergonomic handling in compliance with UNI EN standards and EC Atex directives, our solutions improve safety, optimise workflows, and support continuous, high-quality textile production worldwide.

Challenges in Textile Material Handling

The textile sector involves the constant movement of rolls, reels, cloth, and other bulky or delicate materials across production and logistics lines. These loads are often heavy and awkward to grip, while the fragile nature of fabrics makes them susceptible to creasing, tearing, or contamination if mishandled. Even minor errors in positioning can slow down processes or result in wasted material.

Operators face additional challenges such as repetitive lifting, awkward postures, and the need for precision when aligning rolls or reels with machines. At the same time, textile manufacturers must maintain fast production speeds while ensuring consistent product quality. Meeting these demands requires specialised lift-assist manipulators that provide ergonomic support, precise positioning, and long-term reliability to keep operations safe, efficient, and continuous.

Lift-Assist Solutions for the Textile Sector

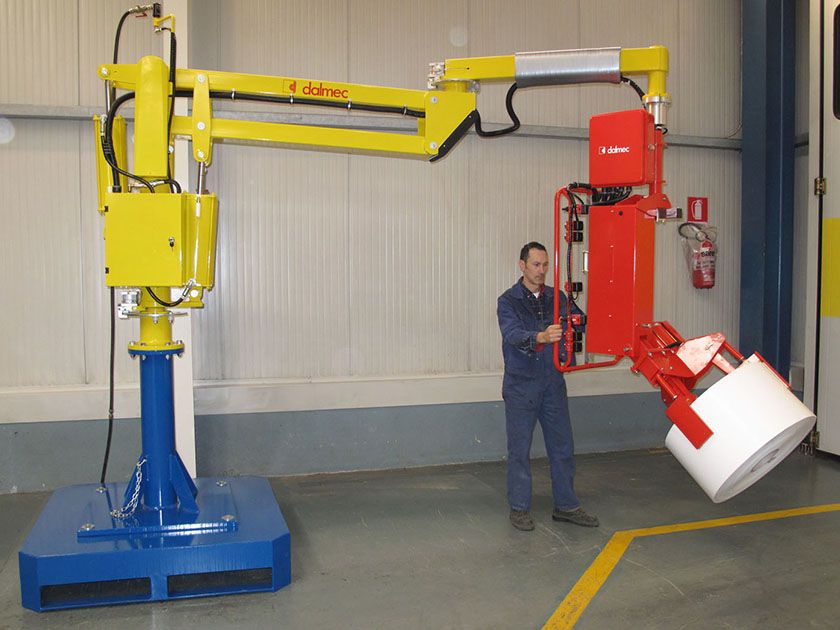

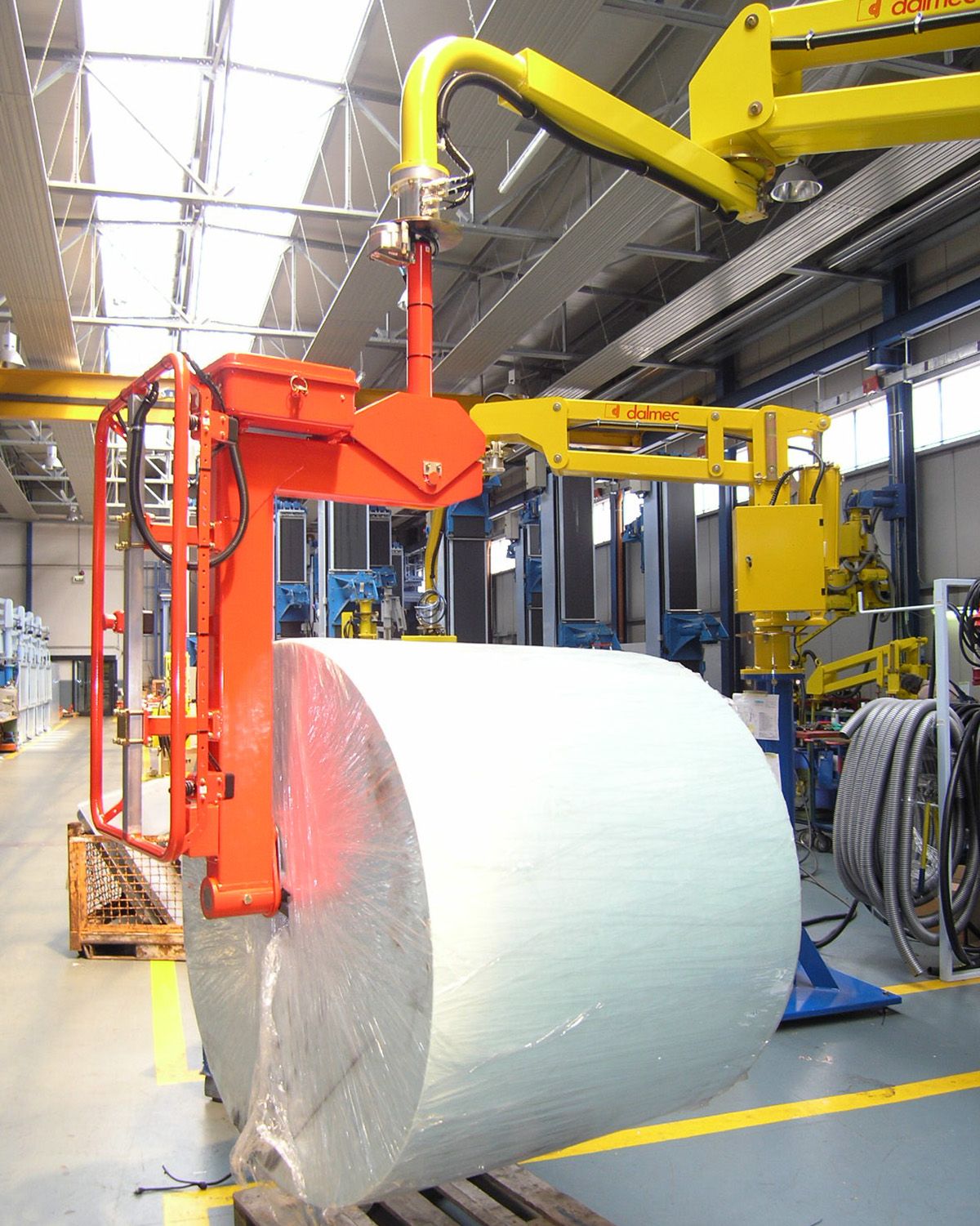

Dalmec offers customised lift-assist manipulators for the textile industry, designed to handle rolls, reels, cloth, and other bulky materials with precision and ergonomics while ensuring safe, continuous production.

-

Pneumatic Balancer Reels: Pneumatic balancer manipulators lift, rotate, and tilt reels of insulating or film materials, ensuring smooth handling of light to medium weight loads.

-

Rolls of Cloth Manipulator: Overhead or column-mounted textile-specific manipulators handle bulky cloth rolls with tooling optimized for gentle, non-abrasive contact.

-

Zero-Weight Balancer for Reels: Zero-gravity manipulators create a weightless effect, enabling operators to position heavy reels accurately with minimal effort.

-

Plastic Film Reel Lifter: Industrial balancers fitted with mandrels or forks lift plastic film reels from cradles and place them onto pallets safely and precisely.

-

Textile Spools / Posifil Spools Handling: Fixed overhead or trolley-mounted manipulators with expanding mandrels grip textile spools via their core to avoid damaging external surfaces.

Benefits of Dalmec Manipulators in the Textile Sector

In the textile industry, where rolls, reels, and spools must be lifted and positioned continuously, Dalmec manipulators deliver essential advantages. By replacing repetitive manual handling with customised lift-assist systems, they protect operators from strain injuries, reduce the risk of fabric damage, and ensure precise alignment of materials with processing machines. Designed to operate reliably over long production cycles, these ergonomic solutions improve safety, maintain product quality, and enhance efficiency across weaving, finishing, packaging, and logistics workflows.

Safe Handling

Safety is paramount in every working environment and the Dalmec Manipulator is designed with safety as a major factor. All Dalmec equipment meets with European standards on safety and the EC Directives on Machinery.

Support

The Dalmec Worldwide network extends support throughout the world to ensure a continuous and competent support throughout the lifetime of the manipulator.

Design

With outstanding design capabilities and over 50 years’ experience, Dalmec offer our expertise and up-to-date design solutions. With constant innovations all solutions are designed to ensure maximum safety.

Ergonomics

Dalmec Manipulators are specifically designed for the manual handling of loads with the reduction of risk and injury, especially to the back and spine, by using best practises in ergonomics.

Reliability

Reliability is important for any manufacturer as downtime can be costly. The Dalmec Manipulator offers the utmost reliability due to expert design solutions and the use of the best quality materials and components.

Productivity

Dalmec Manipulators offer an increase in productivity as operators are able to solely move any product of any weight effortlessly, while at the same time in utmost safety, thereby maximising human resources and increasing productivity.

Customisation & Support

Dalmec industrial manipulators are fully bespoke, tailored to your workflow and environmental conditions. From initial design to final installation, testing, and training, Dalmec engineers are involved at every stage. Our UK service teams provide rapid maintenance and spare parts support, ensuring minimal downtime for your operations.