Ergonomic Lift Assists for Safe and Efficient Vehicle Component Handling

The automotive and industrial vehicle sector requires the handling of a wide range of components, from engines and transmissions to panels, seats, and subassemblies. These parts are often heavy, awkwardly shaped, or require precise positioning on production and packaging lines, making manual handling inefficient and potentially hazardous for operators.

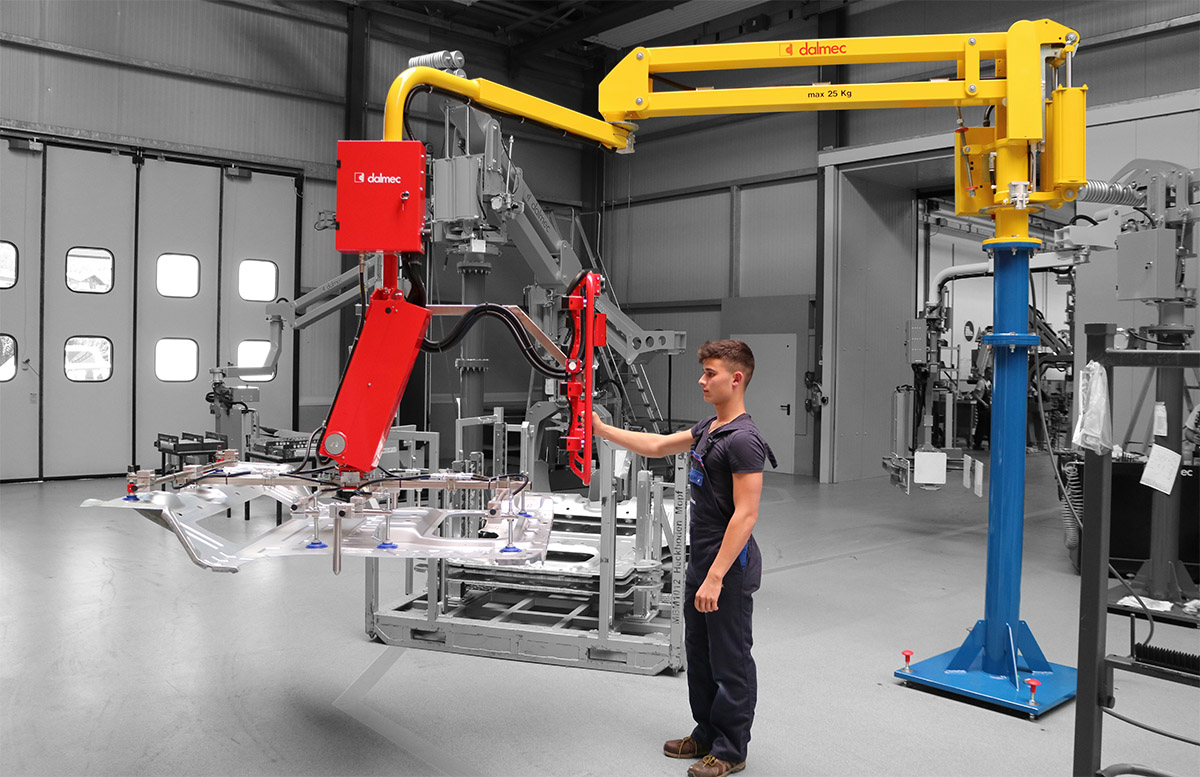

Dalmec industrial manipulators are designed to meet these challenges, providing perfectly weight-balanced movement that allows operators to grip, lift, and position loads in a completely “weightless” condition. Integrated seamlessly with transport and assembly lines, these ergonomic lift assists reduce physical strain, improve safety, and ensure compliance with EU directives while increasing productivity in vehicle manufacturing.

Challenges in Auto and Industrial Vehicle Material Handling

The auto and industrial vehicle sector involves handling a vast range of components, from engines, gearboxes, and axles to body panels, doors, seats, and subassemblies. These parts can be heavy, irregularly shaped, or fragile, requiring careful handling and precise placement during assembly, transport, or packaging. Even small errors in positioning can cause damage, rework, or costly production delays.

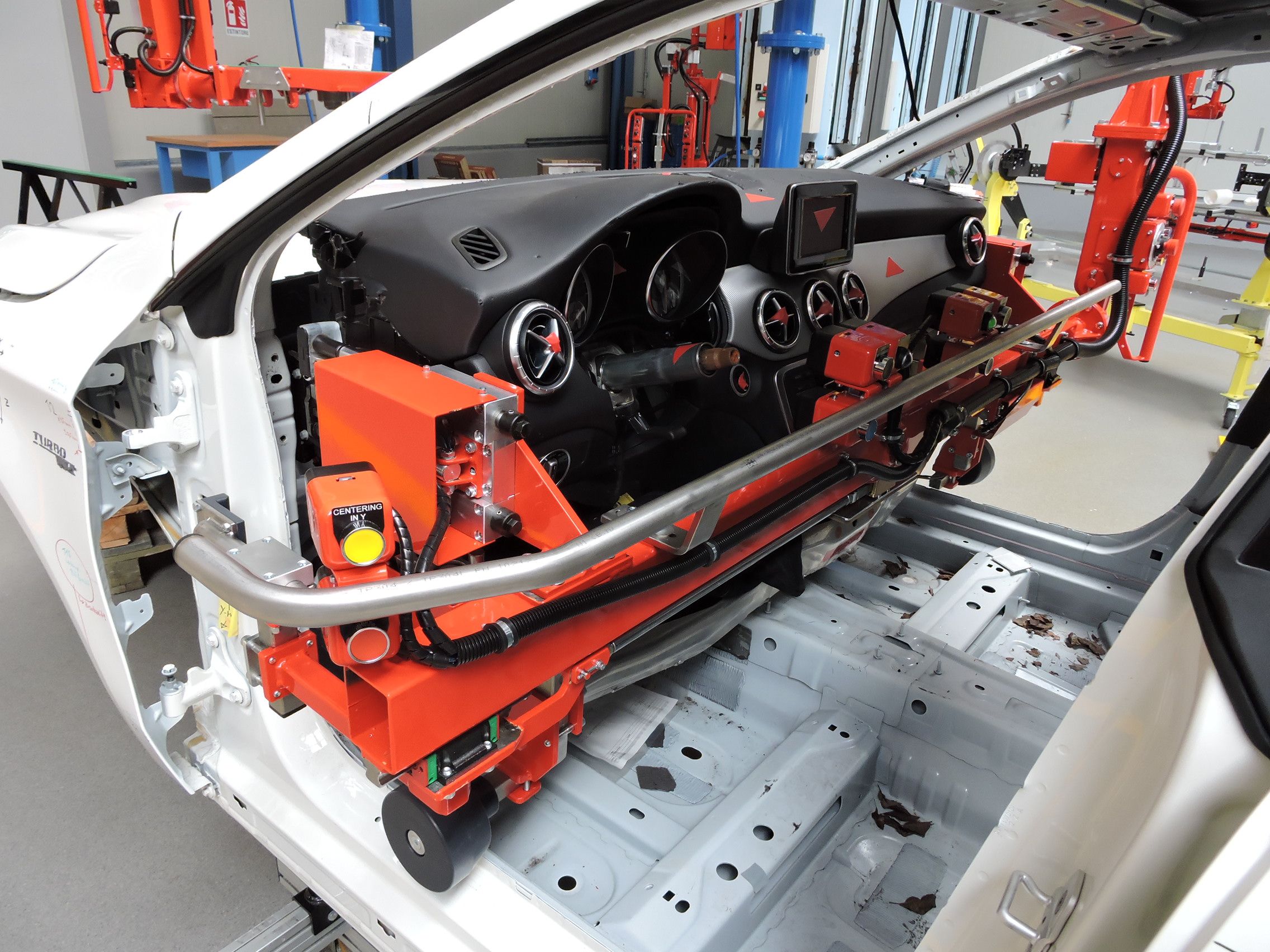

Manual handling of such components exposes operators to significant ergonomic strain, repetitive lifting injuries, and safety risks when dealing with large or awkward parts. At the same time, manufacturers must maintain high-speed production lines and strict quality standards, which demand both precision and efficiency. To meet these challenges, automotive companies require specialised lift-assist manipulators that balance loads perfectly, improve ergonomics, and integrate seamlessly into transport and assembly processes.

Lift-Assist Solutions for the Auto and Industrial Vehicles Sector

Dalmec delivers specialised lift assist manipulators for the mechanical industry, enabling safe and efficient handling of transmission shafts, metal rounds, gears, radiators, axles and other heavy or precision components with minimal operator strain.

-

Bonnets Handling: The Partner fixed overhead manipulator with suction cup tooling grips, lifts and installs front bonnets safely.

-

Rubber Wheel (Raw Tyre) Positioner: The Posifil type manipulator with concentric jaw gripping device is used in overhead version for safe grasping and positioning of raw tyres.

-

Floor Pans Positioner: A Partner Equo manipulator with suction-cup tooling lifts and handles metal sheet floor pans for vehicle assembly.

-

Seat Balancer Device: The Partner Equo overhead trolley-mounted manipulator with pinch-jaws handles and installs vehicle or bus seats of various shapes.

-

Windshield & Glass Handling: Column-mounted manipulators equipped with suction-cup systems allow lifting and placement of vehicle glass or windscreens.

-

Bodywork Panels Handling: Custom manipulators with adapted gripping systems are used to handle bodywork components in various conditions and sizes.

-

Drive Shaft Handling: Balancer manipulators with pinch-jaw gripping enable safe, ergonomic handling of drive shafts in production lines.

-

Battery Handling: Manipulators with tailored gripping tools facilitate safe lifting and positioning of automotive batteries.

-

Dashboard and Interior Components: Custom manipulators handle dashboards and other interior parts with precision and minimal operator effort.

-

Doors Handling: Manipulators with gripping (jaws or suction) systems allow safe, accurate lifting and mounting of vehicle doors.

Benefits of Dalmec Manipulators in the Auto and Industrial Vehicles Sector

In the automotive and industrial vehicle sector, where engines, panels, seats, and other large components must be handled with speed and precision, Dalmec manipulators provide clear advantages. By replacing manual lifting with ergonomic lift-assist systems, they reduce operator strain, minimise the risk of damage to delicate or heavy parts, and ensure accurate placement on fast-moving assembly lines. Built for seamless integration with transport and production processes, these manipulators improve workplace safety, enhance productivity, and help manufacturers maintain consistent quality while complying with stringent safety regulations.

Safe Handling

Safety is paramount in every working environment and the Dalmec Manipulator is designed with safety as a major factor. All Dalmec equipment meets with European standards on safety and the EC Directives on Machinery.

Support

The Dalmec Worldwide network extends support throughout the world to ensure a continuous and competent support throughout the lifetime of the manipulator.

Design

With outstanding design capabilities and over 50 years’ experience, Dalmec offer our expertise and up-to-date design solutions. With constant innovations all solutions are designed to ensure maximum safety.

Ergonomics

Dalmec Manipulators are specifically designed for the manual handling of loads with the reduction of risk and injury, especially to the back and spine, by using best practises in ergonomics.

Reliability

Reliability is important for any manufacturer as downtime can be costly. The Dalmec Manipulator offers the utmost reliability due to expert design solutions and the use of the best quality materials and components.

Productivity

Dalmec Manipulators offer an increase in productivity as operators are able to solely move any product of any weight effortlessly, while at the same time in utmost safety, thereby maximising human resources and increasing productivity.

Customisation & Support

Dalmec industrial manipulators are fully bespoke, tailored to your workflow and environmental conditions. From initial design to final installation, testing, and training, Dalmec engineers are involved at every stage. Our UK service teams provide rapid maintenance and spare parts support, ensuring minimal downtime for your operations.