Safe and Precise Material Handling for Foundry Operations

The foundry industry involves the handling of heavy, hot, and irregularly shaped loads such as rims, moulds, castings, and other foundry pieces of varying dimensions and weights. Manual lifting of these components not only poses serious risks of injury but also threatens product integrity, making efficiency and safety critical at every stage of production.

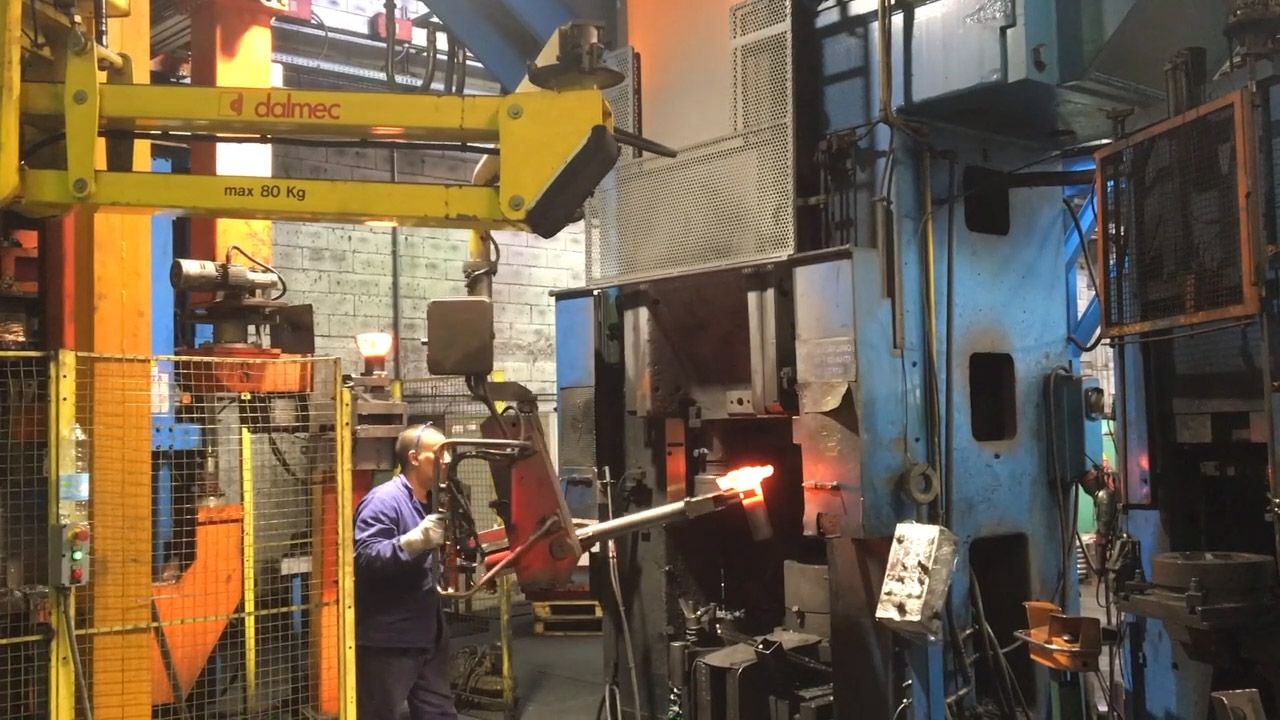

Dalmec industrial manipulators are engineered with customised tooling to grip, lift, tilt, and position foundry parts with ease and precision. Built for demanding environments, they improve operator ergonomics, reduce workplace hazards, and ensure the safe, efficient handling of cast components throughout the manufacturing process.

Challenges in Foundry Material Handling

Foundry operations involve handling extremely heavy, hot, and irregularly shaped loads such as moulds, rims, castings, and precision components. These parts often require careful positioning during pouring, machining, or finishing, where even minor errors can lead to costly defects or production delays.

Manual handling exposes operators to significant risks, including burns, crushing injuries, and musculoskeletal strain from repetitive lifting of awkward loads. At the same time, foundry environments present additional challenges such as high temperatures, dust, and confined working areas. To maintain both safety and productivity, manufacturers need manipulators that provide ergonomic support, precise positioning, and durability to withstand the rigours of continuous foundry use.

Dalmec Lift-Assist Solutions for the Foundry Sector

Dalmec offers specially engineered lift assist manipulators for foundries that safely manage incandescent pieces, alloy discs, casting moulds and mooring chain rings under high-heat, heavy-load, and precision conditions.

-

Alloy Discs Compensator: The Partner Equo compensating arm with pinch jaws grips alloy discs by their outer diameter, rotates them 180° pneumatically, and places them precisely on pallets.

-

Casting Mould Handling: Pneumatic overhead running manipulators with heat-protected pinch jaws lift, tilt, rotate, and place casting moulds weighing from about 5 kg to 900 kg with high ergonomic safety.

-

Mooring Chain Rings Balancer: The Maxipartner column-mounted balancer uses cooled pinch-jaw tooling to safely handle heavy rings of mooring chains, including lifting, rotating, and tilting functions.

-

Incandescent Pieces Lift Assist: The lift assist device for incandescent foundry pieces provides tooling and insulation to support handling glowing hot parts with safety and precision.

Benefits of Dalmec Manipulators in the Foundry Sector

In foundry environments, where heavy, hot, and irregularly shaped loads must be handled daily, Dalmec manipulators deliver significant advantages. By replacing strenuous manual lifting with customised lift-assist solutions, they reduce the risk of operator injuries, improve workplace ergonomics, and ensure precise positioning of moulds, castings, alloy discs, and rings. Built to withstand extreme heat, dust, and continuous use, these manipulators enhance both safety and efficiency, helping foundries achieve consistent quality while minimising downtime and operational costs.

Safe Handling

Safety is paramount in every working environment and the Dalmec Manipulator is designed with safety as a major factor. All Dalmec equipment meets with European standards on safety and the EC Directives on Machinery.

Support

The Dalmec Worldwide network extends support throughout the world to ensure a continuous and competent support throughout the lifetime of the manipulator.

Design

With outstanding design capabilities and over 50 years’ experience, Dalmec offer our expertise and up-to-date design solutions. With constant innovations all solutions are designed to ensure maximum safety.

Ergonomics

Dalmec Manipulators are specifically designed for the manual handling of loads with the reduction of risk and injury, especially to the back and spine, by using best practises in ergonomics.

Reliability

Reliability is important for any manufacturer as downtime can be costly. The Dalmec Manipulator offers the utmost reliability due to expert design solutions and the use of the best quality materials and components.

Productivity

Dalmec Manipulators offer an increase in productivity as operators are able to solely move any product of any weight effortlessly, while at the same time in utmost safety, thereby maximising human resources and increasing productivity.

Customisation & Support

Dalmec industrial manipulators are fully bespoke, tailored to your workflow and environmental conditions. From initial design to final installation, testing, and training, Dalmec engineers are involved at every stage. Our UK service teams provide rapid maintenance and spare parts support, ensuring minimal downtime for your operations.