Industrial Manipulators for Electrical and Electronic Components

The electromechanical sector covers a wide variety of products—ranging from televisions, washing machines, and air conditioners to electrical appliances and complex electronic assemblies. These items often come in bulky, heavy, or awkward shapes that require precise handling to prevent damage during production, assembly, or packaging. Manual lifting can slow down operations and pose risks of strain or injury to operators, making efficient and ergonomic handling systems essential.

Dalmec industrial manipulators provide a reliable solution by offering smooth, weight-balanced movement and custom gripping devices tailored to the unique shapes and sizes of electromechanical products. Whether positioning TV tubes, lifting washing machines, or transferring delicate electrical components, our manipulators ensure safe, precise, and efficient handling. Each system is engineered to improve productivity, reduce manual effort, and guarantee consistent quality across your production line.

Challenges in Electromechanical Material Handling

The electromechanical industry involves handling a wide variety of loads, from large household appliances and heavy air conditioning units to fragile electronic assemblies and TV tubes. These products are often bulky, awkwardly shaped, or highly delicate, which makes manual lifting both inefficient and risky. Even small handling errors can result in scratches, dents, or internal damage, leading to costly rework or product loss.

Operators also face ergonomic challenges, as repetitive lifting of heavy or oversized items increases the risk of musculoskeletal strain and workplace injuries. At the same time, manufacturers must maintain high production speed and accuracy to remain competitive. Balancing safety, efficiency, and precision in these environments requires specialised manipulators that can adapt to different product geometries while ensuring both operator protection and product integrity.

Dalmec Solutions for Electromechanical Material Handling

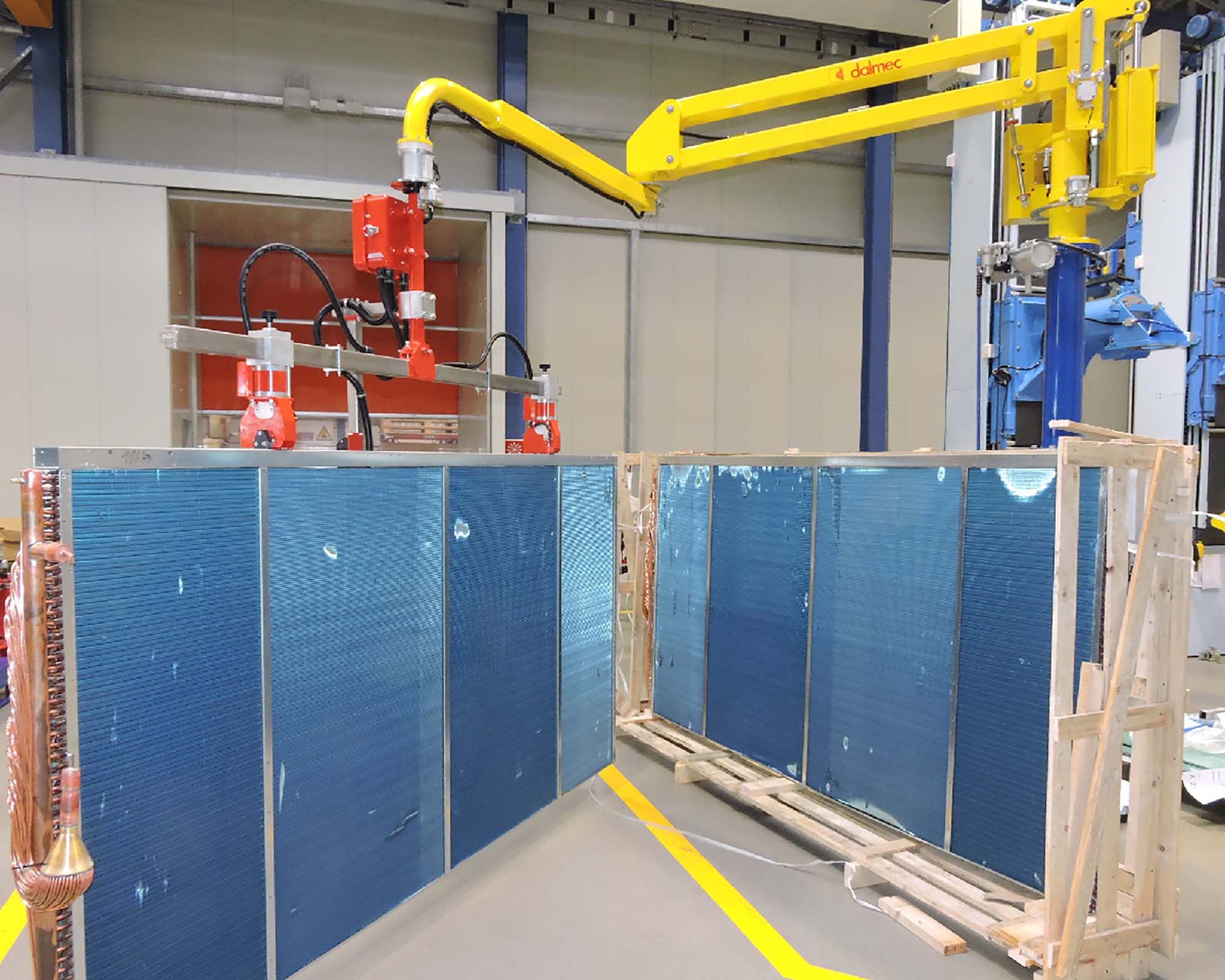

Dalmec offers a wide range of custom industrial manipulators for the electromechanical sector, designed to safely and ergonomically handle everything from washing machines, refrigerators, and boilers to electric motors, photovoltaic panels, satellite components, and other heavy or delicate appliances with precision and reliability.

-

Washing Machine Components: The Partner Equo manipulator with vacuum suction via a multistage Venturi ejector enables precise, safe lifting and positioning of washing machine parts while adhering to UNI EN and ATEX standards.

-

Refrigerator Doors Handling: The Partner Equo column base manipulator equipped with pinch-jaw tooling grips and tilts refrigerator doors from a roller conveyor into assembly cabinets with speed, accuracy, and compliance to EU machinery directives.

-

Silicon Round Bars: A suction-cup-equipped load compensator mounted on the Partner Equo allows safe, ergonomic handling of silicon round bars of varying sizes and weights with precision.

-

Zero-Gravity Balancers: Dalmec’s zero balancers offer effortless handling of heavy or awkward loads (up to 1,500 kg), enabling smooth, weightless manipulation across extended reaches.

-

Boiler Handling Arm: A fixed overhead manipulator fitted with Dalmec pinch jaws provides safe and precise lifting for heavy boilers.

-

Electric Insulator Handling: The Maxipartner column manipulator with self-centering jaw tooling handles electrical insulators of varying shapes and weights with precision and reliability.

-

Glass Door Handling: A Partner Equo column manipulator, fitted with suction cups for 360° manual rotation, enables safe and precise handling of fragile glass doors.

-

Radiator & Air-Conditioner Handling: Equipped with specially designed jaws, the Maxipartner column-mounted manipulator handles bulky radiators and air conditioners ergonomically and safely.

-

Electric Motor Assembly: The Partner balancer, with an integrated magnet tool, allows safe and efficient handling and assembly of electric motors.

-

Lawnmower Handling: A Partner balancer with jaw tooling supports safe handling and packaging of heavy lawnmowers with minimal operator effort.

-

Photovoltaic Panel Tilting: A Partner manipulator with suction cup tooling enables manual tilting and ergonomic handling of large photovoltaic panels.

-

Washing Machine Drum Handling: The Partner fixed overhead balancer, using jaw tooling and a pneumatic 90° tilt, handles washing machine drums precisely and ergonomically

-

General Electrical Appliance Handling

Dalmec manipulators fitted with tailored gripping tools enhance the safe and ergonomic handling of various electrical appliances and components.

Benefits of Dalmec Manipulators in Electromechanical Material Handling

In the electromechanical sector, handling bulky appliances, heavy equipment, and delicate electronic components requires solutions that balance safety, ergonomics, and precision. Dalmec manipulators are engineered to reduce manual strain, protect fragile parts from damage, and streamline workflows across assembly and packaging lines. By combining custom gripping tools, weight-balanced movement, and compliance with strict European safety standards, our solutions improve operator wellbeing, increase productivity, and ensure consistent quality in every stage of electromechanical manufacturing.

Safe Handling

Safety is paramount in every working environment and the Dalmec Manipulator is designed with safety as a major factor. All Dalmec equipment meets with European standards on safety and the EC Directives on Machinery.

Support

The Dalmec Worldwide network extends support throughout the world to ensure a continuous and competent support throughout the lifetime of the manipulator.

Design

With outstanding design capabilities and over 50 years’ experience, Dalmec offer our expertise and up-to-date design solutions. With constant innovations all solutions are designed to ensure maximum safety.

Ergonomics

Dalmec Manipulators are specifically designed for the manual handling of loads with the reduction of risk and injury, especially to the back and spine, by using best practises in ergonomics.

Reliability

Reliability is important for any manufacturer as downtime can be costly. The Dalmec Manipulator offers the utmost reliability due to expert design solutions and the use of the best quality materials and components.

Productivity

Dalmec Manipulators offer an increase in productivity as operators are able to solely move any product of any weight effortlessly, while at the same time in utmost safety, thereby maximising human resources and increasing productivity.

Customisation & Support

Dalmec industrial manipulators are fully bespoke, tailored to your workflow and environmental conditions. From initial design to final installation, testing, and training, Dalmec engineers are involved at every stage. Our UK service teams provide rapid maintenance and spare parts support, ensuring minimal downtime for your operations.