Industrial Manipulators for Safe, Ergonomic Handling, Inclination & Positioning of Reels

Dalmec industrial manipulators are used worldwide to lift, turn, and position reels and bobbins of paper, film, foil, fabric, nonwovens, label stock, wire and more—moving product from pallets to unwind/rewind stands, feeding converting and printing lines, or transferring between processes. With application-specific gripping devices—expanding mandrels for core pick-up (e.g., 3″–6″), side-clamp jaws for coreless or soft reels, vacuum pads/frames for delicate surfaces, and tilting/rotating heads (0–90–180°)—operators can lift, rotate, and precisely place loads from 5 kg up to 900 kg with smooth, weight-balanced control, improving throughput while reducing strain and product damage.

At Dalmec, safety and customization are at the core of every solution. All manipulators are manufactured in conformity with UNI EN standards, EC ATEX directives, and international safety guidelines. From functional analysis and technical design through simulations, prototype creation, and final implementation, our engineers work in close partnership with clients—performing continuous checks and reviews throughout development—to deliver state-of-the-art handling systems tailored to specific production needs.

Dalmec Manipulators for Reels & Bobbins

Dalmec manipulators for reels provide safe, repeatable, and efficient handling across packaging, printing & converting, textiles, cable and wire, and warehouse logistics. Tooling options include pneumatic expanding mandrels for quick in-core engagement, band or jaw grippers for wrapped or coreless reels, vacuum end-effectors for surface-critical materials, and powered or manual tilt/rotation for horizontal-to-vertical changeovers and accurate alignment at chucks or shafts. Systems can be configured in column, overhead, or trolley-mounted executions for long reach and clear floors, with low-headroom variants for tight spaces; options include stainless finishes, anti-marking contact surfaces, dust-management for paper lines, and ATEX-rated setups for solvent environments. Whether picking reels from pallets, chucking to an unwind, flipping for inspection, or staging finished rolls, Dalmec solutions enable continuous, reliable operation and measurable gains in safety, quality, and productivity.

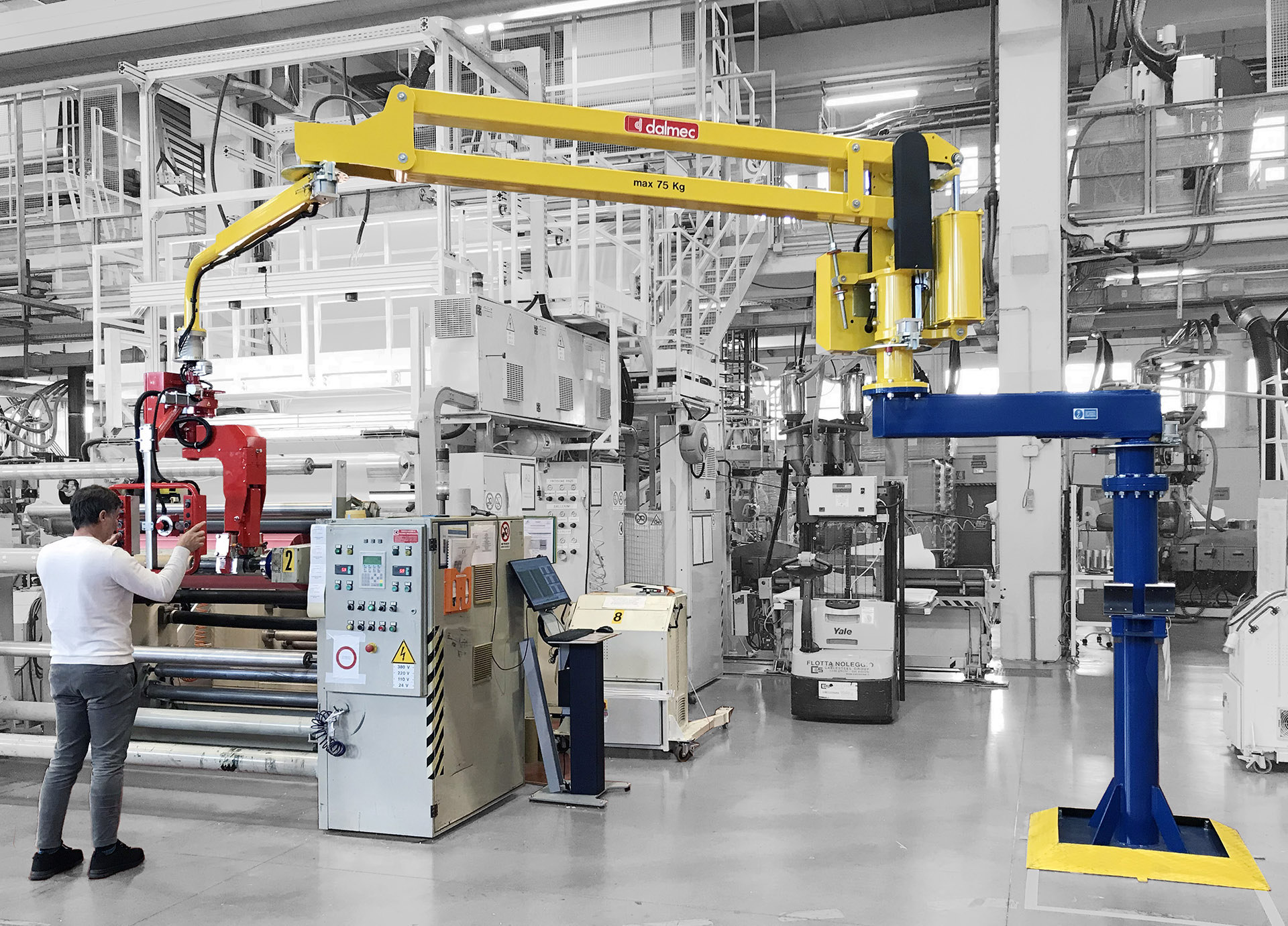

Offset Column — Partner Manipulator for Reel-Carrier Shafts

An offset-column Partner manipulator with a jaw-type gripper engages reel-carrier shafts on the terminal end and, thanks to the offset arm’s extended reach, lets operators insert the shaft into the reel core and manoeuvre loads smoothly across the working area (approx. 75 kg capacity, ~6500 mm radius, ~1400 mm vertical lift).

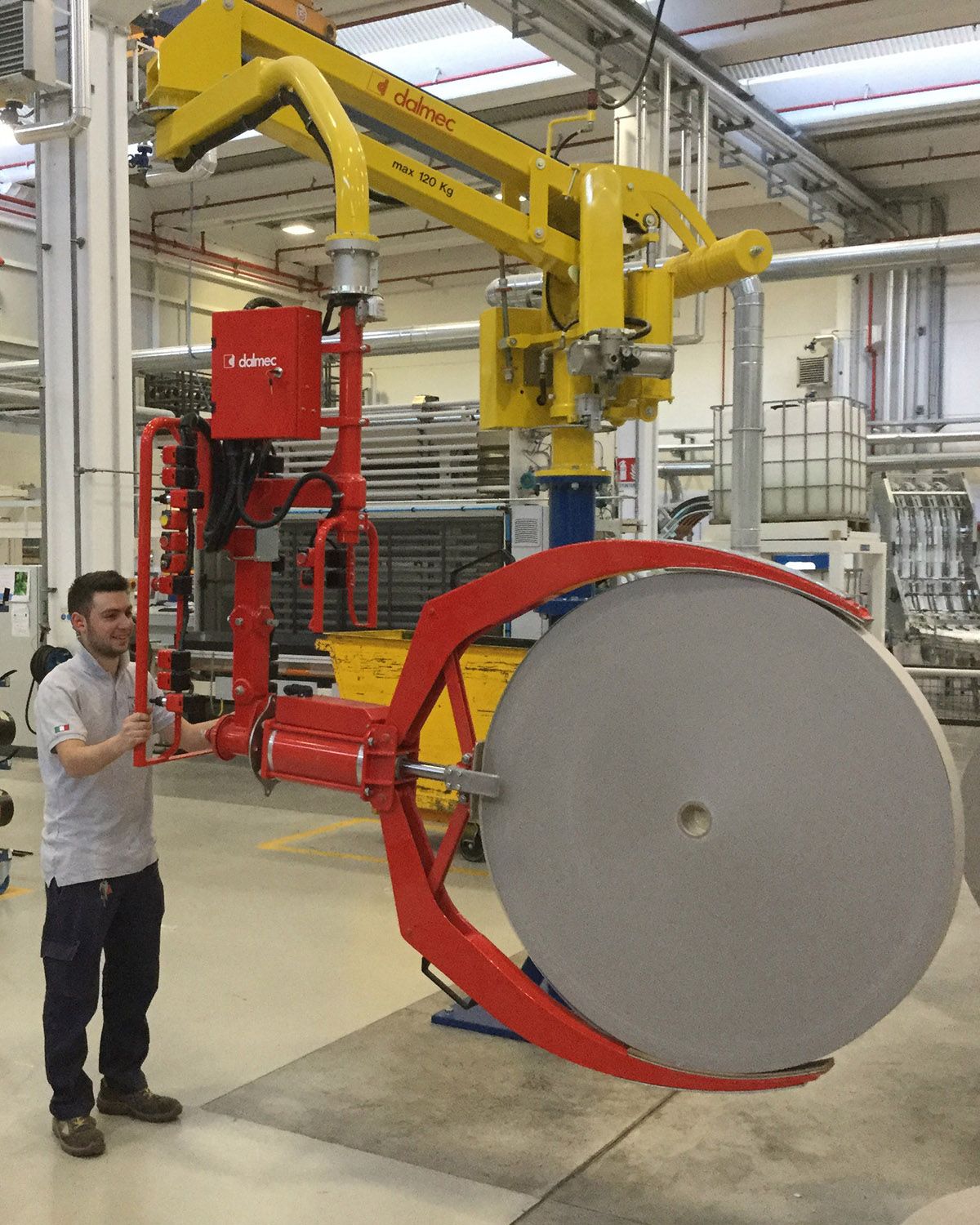

Maxipartner Manipulator for Handling Reels of Insulation Material

A column-mounted Maxipartner with interchangeable self-centring jaws grips reels on the outer diameter and provides pneumatic 90° tilt for precise pallet-to-machine transfers, supporting heavy reels with up to ~900 kg capacity and ~4500 mm working radius.

Handling Systems for Reels — Maxipartner MXC

Custom Maxipartner MXC systems handle reels up to about 500 kg with large envelopes (radius up to ~4500 mm, vertical lift to ~2600 mm), enabling ergonomic pick, tilt and place of insulation reels via portable baseplates and dedicated tooling.

Reel-Carrier Shafts — Jaw Tooling for Core Insertion

A Partner manipulator with specialized jaws grips reel-carrier shafts on the end face so the operator can slide the shaft into the reel core and handle different diameters safely and repeatably.

Tanks – Overhead Partner with Jaws

Overhead Partner with jaws enables ergonomic pick-and-place of tanks across the work area with risk-assessed, standards-compliant safety.

Pneumatic Lifter for Reels — Partner with Self-Centering Jaws

A column-mounted Partner “pneumatic lifter” picks horizontal reels from a winding shaft, pneumatically rotates them 90°, and sets them vertically on a pallet using self-centring jaws for fast, ergonomic changeovers.

Reels — Industrial Balancer for Plastic-Film Reels

A column-mounted industrial balancer with mandrel tooling grips inside the core, provides 90° tilting, and handles plastic-film reels efficiently with capacities around 250 kg for safe pallet-to-shaft operations.

Wire Coils — Partner Manipulator with Pinch-Jaw Gripper

Designed for pallet-to-winder moves, a column-mounted manipulator uses pinch jaws on the coil’s outer edge and a pneumatic 90° inclination to position wire coils accurately while maintaining ergonomic, weight-balanced control.

Packaging Line — Mandrel Handling of Bobbins

For packaging lines, a Partner manipulator fitted with a mandrel tool picks and transports bobbins, with options like forklift-movable baseplates so the same unit can serve multiple workstations and line positions.

Posivel for Reels — Compact Mandrel Handling (Up to ~60 kg)

A Posivel manipulator, column-mounted on a portable baseplate, uses a pneumatic mandrel to grip in the reel core and provide 90° inclination for light reels, with typical specs around 60 kg capacity, ~2600 mm radius and ~1700 mm vertical lift.