Industrial Manipulators for Safe, Ergonomic Loading & Unloading of Panels

Dalmec industrial manipulators are used worldwide to lift, orient, and position wood, MDF, plywood, laminate, composite, and metal panels for CNC routers, beam saws, edgebanders, presses, and finishing lines. With application-specific gripping devices—vacuum frames with zoning, adjustable crossbars, magnetic/vacuum combinations, and tilting/rotating heads—operators can pick, align, flip, and place single sheets or stacks from 5 kg up to 900 kg with smooth, precise control, improving throughput while reducing operator strain and panel damage.

At Dalmec, safety and customization are at the core of every solution. All manipulators are manufactured in conformity with UNI EN standards, EC ATEX directives, and international safety guidelines. From functional analysis and technical design through simulations, prototype creation, and final implementation, our engineers work in close partnership with clients—performing continuous checks and reviews throughout development—to deliver state-of-the-art handling systems tailored to specific production needs.

Dalmec Manipulators for Panels – Machine Loading & Unloading

Dalmec manipulators for panels ensure safe, repeatable, and efficient handling at the infeed/outfeed of processing equipment and across internal logistics cells. Tooling options include multi-zone vacuum frames for mixed sizes, narrow bars for small offcuts, swivel/tilt units (0–90–180°) for orientation and inspection, and low-headroom executions for tight lines; systems can be configured for dusty environments (woodworking), anti-marking pads for finished surfaces, stainless or wash-down finishes for special areas, and ATEX-rated setups where required. Whether de-stacking blanks to a CNC, feeding an edgebander, turning sheets for a second pass, or palletising finished panels, Dalmec solutions enable continuous, reliable operation and measurable gains in safety, quality, and productivity.

Panels Lifter — Maxipartner/Partner Solutions for Heavy Sheets

Designed for single sheets or stacked panels, this lifter—available in column-mounted executions with custom vacuum tooling—delivers weight-balanced, precise handling and can be configured up to a 900 kg capacity with large working reaches and ergonomic controls for safe, repeatable loading/unloading.

Handling Device for Wooden Panels — Vacuum Frame with Zoning

A Dalmec manipulator fitted with adjustable suction-cup tooling (including multi-zone vacuum frames) grips, tilts and positions wooden panels of varying sizes to reduce operator effort and speed machine feeding in woodworking lines.

Lifting Arm for Panels — Column-Mounted Partner

This lifting arm uses a Partner manipulator with adjustable suction cups to pick panels from a roller conveyor and accurately place them on pallets, providing smooth, ergonomic handling across the working envelope.

Panels & Plastic Profiles — Custom Manipulators for Mixed Geometries

Dalmec builds application-specific manipulators with tailored dimensions and picking systems for panels and plastic profiles, enabling safe, efficient transfer and orientation even with varied lengths and cross-sections.

Lifting Arm for Panels — Zero-Gravity Handling for Sheets

A pneumatic lifting arm with adjustable suction cups provides “weightless” control to grip, rotate and set panels of many materials and sizes, improving throughput while reducing strain.

Manipulator for Panels — Partner Equo with Adjustable Suction Cups

A Partner, column-mounted manipulator equipped with manually adjustable suction cups handles panels or sheets quickly and securely; vacuum is generated by a Venturi ejector to adapt to different panel dimensions.

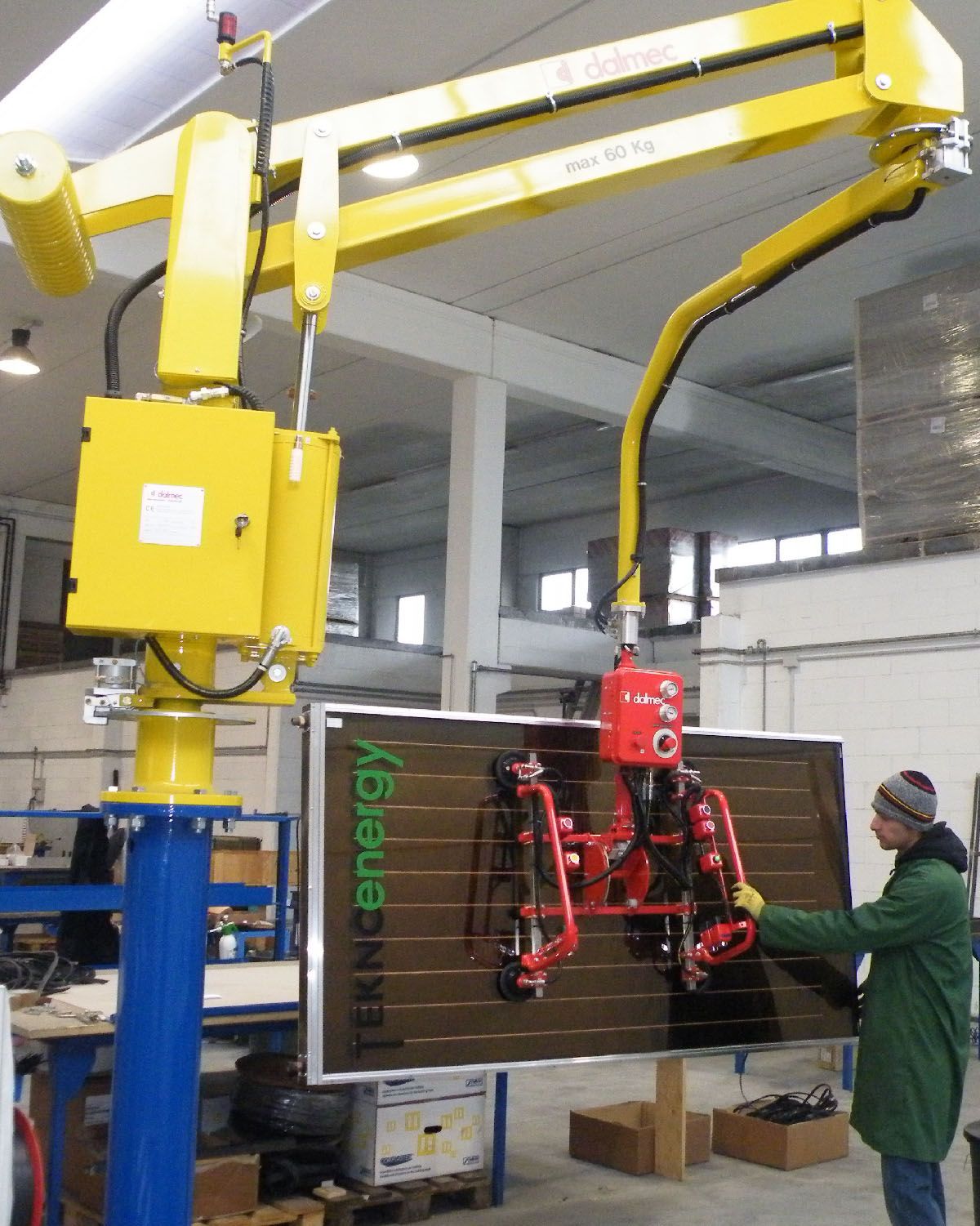

Photovoltaic Panels — Suction-Cup Handling with Manual Tilt

A Partner-type manipulator with a dedicated suction-cup frame allows safe gripping and manual inclination of photovoltaic panels for assembly and line transfer.

Handling Systems — Vertical Rails with Overhead Tracking

A Partner Equo manipulator rides on a vertically positioned overhead tracking system using U-shaped aluminium rails with stiffening ribs and end buffers, enabling precise handling of doors and similar panels along guided paths.