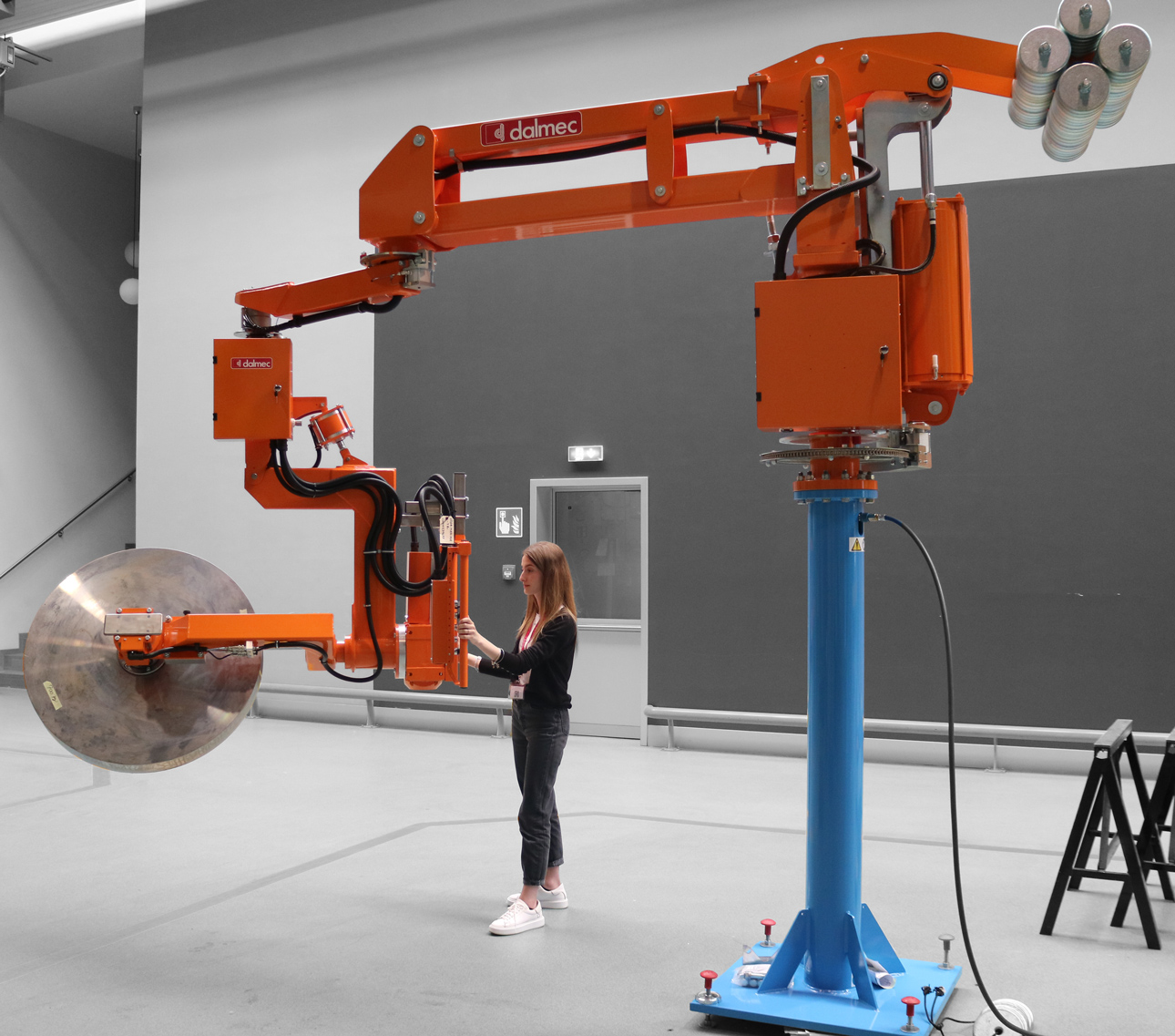

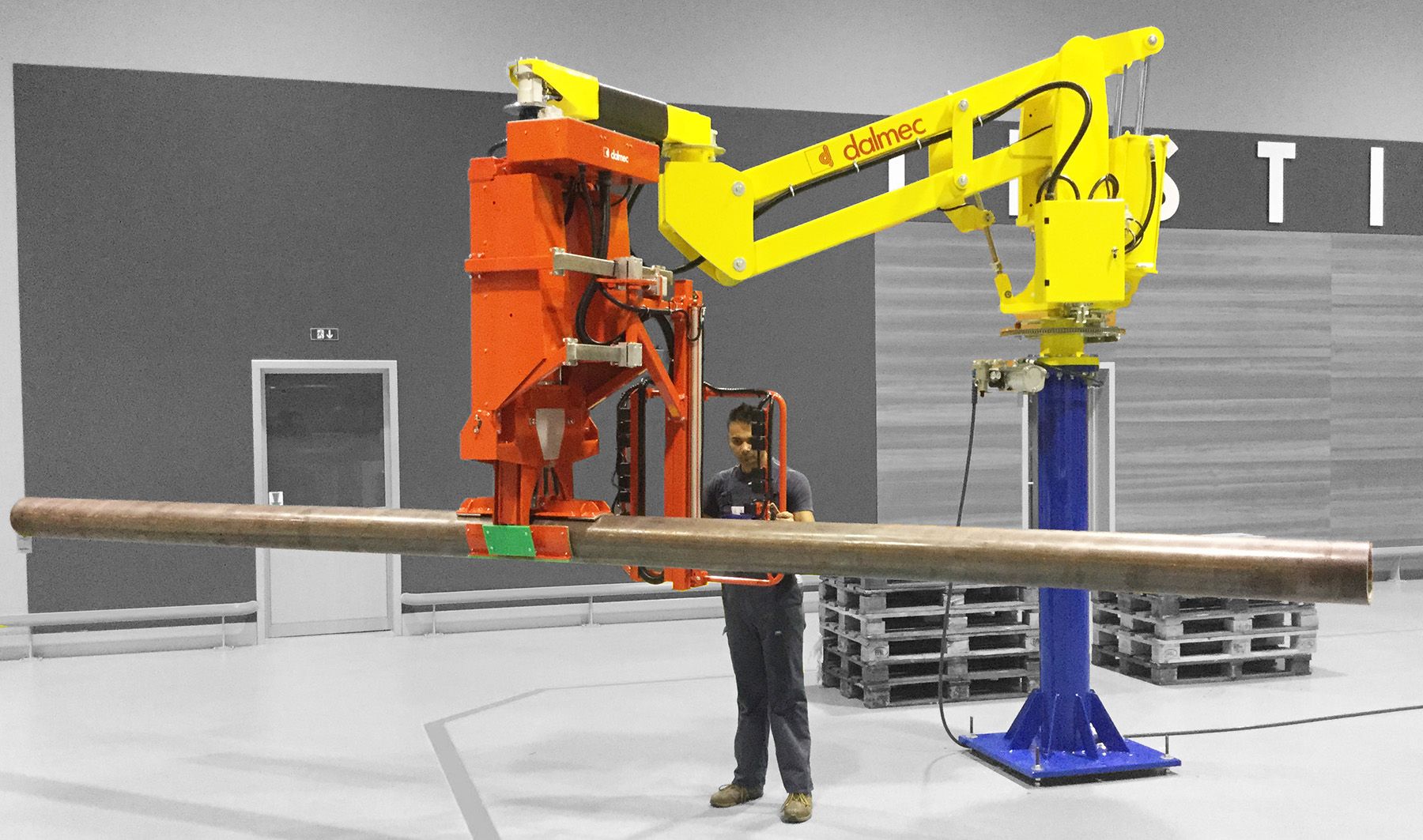

Safe and Efficient Material Handling for Mechanical Components

The mechanical industry involves the handling of a wide range of products such as transmission shafts, leaf springs, gears, metal sheets, tanks, and rolls, all varying in weight and dimension. These components are often heavy, awkwardly shaped, or precision-engineered, which makes manual lifting inefficient and potentially hazardous for both operators and products.

Dalmec industrial manipulators are designed with customised tooling to provide ergonomic, weight-balanced handling of mechanical parts. By enabling operators to grip, lift, tilt, and position loads with ease, they ensure safe and efficient workflows while protecting product integrity and reducing the risk of workplace injuries.

Challenges in Mechanical Material Handling

The mechanical sector requires the movement of heavy, bulky, and precision-engineered components such as transmission shafts, gears, tanks, rolls, and metal sheets. These loads often have irregular shapes and demanding weight ranges, making manual handling both unsafe and inefficient. Even minor mishandling can result in damage to high-value components or costly production delays.

Operators face additional challenges, including repetitive lifting injuries, ergonomic strain, and the need for exact positioning during assembly, machining, or packaging. At the same time, manufacturers must maintain fast production speeds without compromising on quality or safety. Meeting these challenges requires specialised manipulators capable of adapting to different load geometries while ensuring precision, durability, and operator protection in demanding environments.

Lift-Assist Solutions for the Mechanical Sector

Dalmec offers a wide range of lift-assist manipulators engineered for the food industry that provide hygienic, ergonomic, and safe handling of cheeses, frozen meat, barrels, yogurts, boxes, bags, water jugs, and other varied food products—minimising manual strain, protecting product integrity, and ensuring compliance with food safety regulations.

-

Cardboard Packages Balancer: The Partner Equo balancer with jaws gripping system safely picks up and overturns large cardboard packaging with capacities up to ~30 kg.

-

Handling of Cheeses: Pneumatic manipulators with pinch-jaw tooling enable fast, precise, and ergonomic handling of cheeses with or without packaging.

-

Plastic Container Handling: Partner Equo manipulators with pinch jaws grip one to three food containers from roller conveyors and position them accurately on pallets.

-

Wooden Barrels Lifting: Partner Equo manipulators with pinch-jaw tooling ensure safe and efficient lifting and movement of heavy wooden barrels.

-

Frozen Meat Handling: Stainless-steel manipulators fitted with hooks provide hygienic and safe handling of frozen meat blocks or cuts.

-

Bag Handling (Tomato Concentrate): Partner type manipulators pick up heavy bags of tomato concentrate from crates and place them on conveyors with minimal operator effort.

-

Zero Balancer for Boxes: Zero-gravity balancers allow effortless and precise lifting of boxes filled with bottles or packaged food items.

-

Yoghurt Packs Handling: Partner Equo manipulators with retractable fork tooling make lifting and stacking yoghurt packs safe, quick, and ergonomic.

-

Water Jugs Handling: Manipulators with vacuum gripping systems handle multiple water jugs at once, streamlining packaging and palletising.

-

Metal Drum Handling: Pinch-jaw equipped manipulators provide safe and efficient lifting of heavy metal drums in food production facilities.

Benefits of Dalmec Manipulators in the Mechanical Sector

In the mechanical sector, where components like shafts, gears, tanks, and profiles can be both heavy and precision-engineered, Dalmec manipulators provide a clear advantage. By replacing manual lifting with customised lift-assist systems, they reduce the risk of workplace injuries, improve ergonomics, and enable operators to handle loads effortlessly with accuracy. Each manipulator is designed to deliver precise positioning, robust performance, and compliance with strict safety standards, helping manufacturers protect their workforce, safeguard product quality, and maintain efficient, uninterrupted production.

Safe Handling

Safety is paramount in every working environment and the Dalmec Manipulator is designed with safety as a major factor. All Dalmec equipment meets with European standards on safety and the EC Directives on Machinery.

Support

The Dalmec Worldwide network extends support throughout the world to ensure a continuous and competent support throughout the lifetime of the manipulator.

Design

With outstanding design capabilities and over 50 years’ experience, Dalmec offer our expertise and up-to-date design solutions. With constant innovations all solutions are designed to ensure maximum safety.

Ergonomics

Dalmec Manipulators are specifically designed for the manual handling of loads with the reduction of risk and injury, especially to the back and spine, by using best practises in ergonomics.

Reliability

Reliability is important for any manufacturer as downtime can be costly. The Dalmec Manipulator offers the utmost reliability due to expert design solutions and the use of the best quality materials and components.

Productivity

Dalmec Manipulators offer an increase in productivity as operators are able to solely move any product of any weight effortlessly, while at the same time in utmost safety, thereby maximising human resources and increasing productivity.

Customisation & Support

Dalmec industrial manipulators are fully bespoke, tailored to your workflow and environmental conditions. From initial design to final installation, testing, and training, Dalmec engineers are involved at every stage. Our UK service teams provide rapid maintenance and spare parts support, ensuring minimal downtime for your operations.